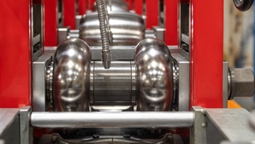

Rolls / Dies

PDS Makina is engaged in the production and design of pipe-profile and any and all kinds of moulds with custom shapes. Production and design of pipe-profile mould requires experience. PDS Makina has gained experience both in design and mould production for long years and integrated its experience with its engineering techniques.

MOULD

Mould designs are carried out with the best and most developed CAD software in the sector. After the tube-profile development has been achieved as a result of the data obtained from the machine and analyzed by the DTM (Deformation Technology Module) module, one-to-one simulation of the molds formed with the finite elements module are made after the molding process has been carried out based on experiences and engineering know-how. Then, the production process starts for the design, which is ready to be manufactured, with the CNC machines based on the CAM data obtained from the said CAD software. Moulds, which are produced from cold work tool steel and put to ultrasonic crack control are vacuum heat-treated in the hi-tech heat-treatment labs. Special grinders and CNC machines apply finishing processes subsequent to the said heat-treatment. Finally, he molds are delivered to the customer. Our company assists its customers in terms of mold rectifications. We manufacture custom Tungsten carbide molds in accordance with our customer demands. Service life of these molds are twice more than those which are made of cold work tool steel.